Working principle of large industrial steam jacketed kettle

The working principle of the steam jacketed kettle with mixer uses counter-pressure cooking. Simply put, compressed air is used to pass into the pot to increase the pressure to prevent the cans from protruding and the lid from jumping. The manufacturer of the steam jacketed kettle introduces the operating procedures of the steam jacketed kettle.

Because compressed air is a poor heat conductor, and the steam itself has a certain pressure. Therefore, do not put in compressed air during the process of sterilization and heating, but only need to be in a heat preservation state after reaching the sterilization temperature. After the sterilization is completed, when the temperature is cooled down, the steam supply is stopped, and the cooling water is forced into the spray pipe. As the temperature in the pot drops, the steam condenses, and the internal force of the pot is reduced, and the pressure of compressed air is used to compensate. During the sterilization process, attention should be paid to the initial exhaust method, and then the steam is released to allow the steam to circulate. It can also deflate every 15 to 20 minutes to promote heat exchange. In short, the sterilization conditions must be met and carried out according to certain procedures. The sterilization temperature, sterilization pressure, sterilization time and operation methods are all specified by the canned product sterilization process.

The steam jacketed kettle is a widely used food machinery and equipment, with a large market share, and most food factories may use it.

1. Introduction of steam jacketed kettle with mixer

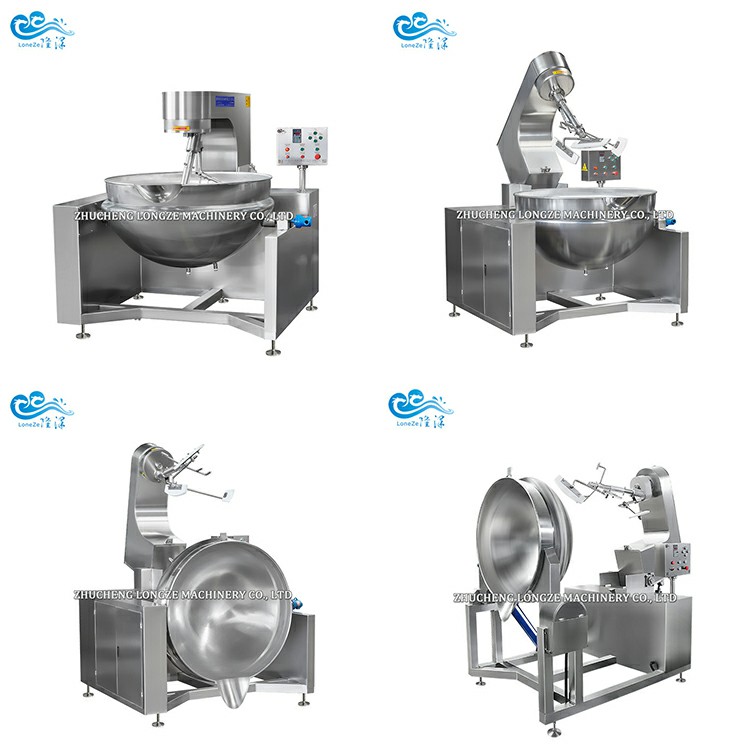

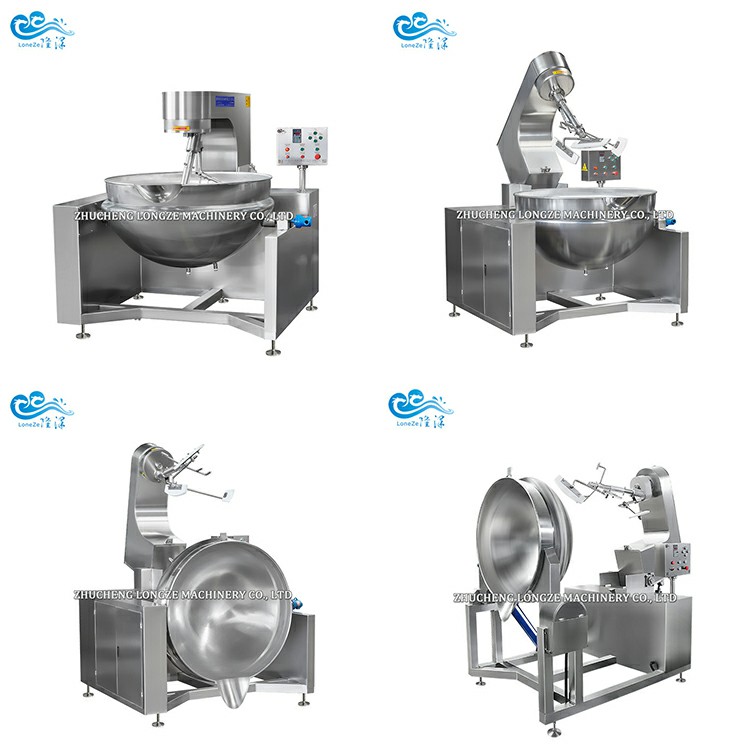

Steam jacketed kettle with mixer is also called steam pot, cooking pot, and jacketed steam pot. It usually consists of a pot body and legs. The pot body of the steam jacketed kettle with mixer is a double-layer structure composed of an inner and outer spherical pot body, and the middle jacket is heated by steam. There are fixed type, inclined type and stirring type. The steam jacketed kettle has the characteristics of large heating area, high thermal efficiency, uniform heating, short boiling time of liquid materials, easy control of heating temperature, beautiful appearance, convenient installation, convenient operation, safety and reliability. The steam jacketed kettle with mixer is widely used in the processing of various foods, and can also be used in large-scale restaurants or canteens for boiling soup, cooking, stew, and porridge. It is a good equipment for improving quality, shortening time and improving working conditions in food processing.

2. the working principle of the steam jacketed kettle with mixer

The fixed type is mainly composed of a pot body and feet; the inclined type is mainly composed of a pot body and an inclined frame; the stirring type is mainly composed of a pot body and a stirring device. The steam jacketed kettle can also use a certain pressure of steam as a heat source or electric heating. The steam jacketed kettle has the characteristics of large heating area, high thermal efficiency, uniform heating, short boiling time of liquid materials, and easy control of heating temperature. The inner pot body (inner pot) of the steam jacketed kettle with mixer is made of acid-resistant and heat-resistant stainless steel, equipped with pressure gauge and safety valve, beautiful appearance, convenient installation, convenient operation, safe and reliable.

3.steam jacketed kettle with mixer structure:

The steam jacketed kettle with mixer is mainly composed of a pot body and an inclined frame or support angle; the pot body is a double-layer structure composed of an inner spherical pot body and an outer spherical pot body, and the middle layer is filled with heat-conducting oil or water.

4. Material of steam jacketed kettle with mixer body:

(a) Inner pot body stainless steel (SUS304/SUS316L) and outer pot body carbon steel (Q235-B), coated with anti-rust paint;

(b) Both the inner and outer pots are stainless steel (SUS304/SUS316L).

The working principle of the steam jacketed kettle with mixer uses counter-pressure cooking. Simply put, compressed air is used to pass into the pot to increase the pressure to prevent the cans from protruding and the lid from jumping. The manufacturer of the steam jacketed kettle introduces the operating procedures of the steam jacketed kettle.

Because compressed air is a poor heat conductor, and the steam itself has a certain pressure. Therefore, do not put in compressed air during the process of sterilization and heating, but only need to be in a heat preservation state after reaching the sterilization temperature. After the sterilization is completed, when the temperature is cooled down, the steam supply is stopped, and the cooling water is forced into the spray pipe. As the temperature in the pot drops, the steam condenses, and the internal force of the pot is reduced, and the pressure of compressed air is used to compensate. During the sterilization process, attention should be paid to the initial exhaust method, and then the steam is released to allow the steam to circulate. It can also deflate every 15 to 20 minutes to promote heat exchange. In short, the sterilization conditions must be met and carried out according to certain procedures. The sterilization temperature, sterilization pressure, sterilization time and operation methods are all specified by the canned product sterilization process.

The steam jacketed kettle is a widely used food machinery and equipment, with a large market share, and most food factories may use it.

1. Introduction of steam jacketed kettle with mixer

Steam jacketed kettle with mixer is also called steam pot, cooking pot, and jacketed steam pot. It usually consists of a pot body and legs. The pot body of the steam jacketed kettle with mixer is a double-layer structure composed of an inner and outer spherical pot body, and the middle jacket is heated by steam. There are fixed type, inclined type and stirring type. The steam jacketed kettle has the characteristics of large heating area, high thermal efficiency, uniform heating, short boiling time of liquid materials, easy control of heating temperature, beautiful appearance, convenient installation, convenient operation, safety and reliability. The steam jacketed kettle with mixer is widely used in the processing of various foods, and can also be used in large-scale restaurants or canteens for boiling soup, cooking, stew, and porridge. It is a good equipment for improving quality, shortening time and improving working conditions in food processing.

2. the working principle of the steam jacketed kettle with mixer

The fixed type is mainly composed of a pot body and feet; the inclined type is mainly composed of a pot body and an inclined frame; the stirring type is mainly composed of a pot body and a stirring device. The steam jacketed kettle can also use a certain pressure of steam as a heat source or electric heating. The steam jacketed kettle has the characteristics of large heating area, high thermal efficiency, uniform heating, short boiling time of liquid materials, and easy control of heating temperature. The inner pot body (inner pot) of the steam jacketed kettle with mixer is made of acid-resistant and heat-resistant stainless steel, equipped with pressure gauge and safety valve, beautiful appearance, convenient installation, convenient operation, safe and reliable.

3.steam jacketed kettle with mixer structure:

The steam jacketed kettle with mixer is mainly composed of a pot body and an inclined frame or support angle; the pot body is a double-layer structure composed of an inner spherical pot body and an outer spherical pot body, and the middle layer is filled with heat-conducting oil or water.

4. Material of steam jacketed kettle with mixer body:

(a) Inner pot body stainless steel (SUS304/SUS316L) and outer pot body carbon steel (Q235-B), coated with anti-rust paint;

(b) Both the inner and outer pots are stainless steel (SUS304/SUS316L).

Contact Us:

Shandong Longze Machinery Co.,Ltd

Company website:https://www.firemixer.com/

WhatsApp/Wechat:0086 13153609533

Tel:0086 13153609533

E-mail:rena@loneze.com

Address:Zhucheng Economic Development Zone, Shandong Province, the first five lines west

Contact:Ms. Rena

If you have any question you can contact me ,i can give you the lowest discount.

Please fill in the form and leave a clear message. We will contact you immediately.