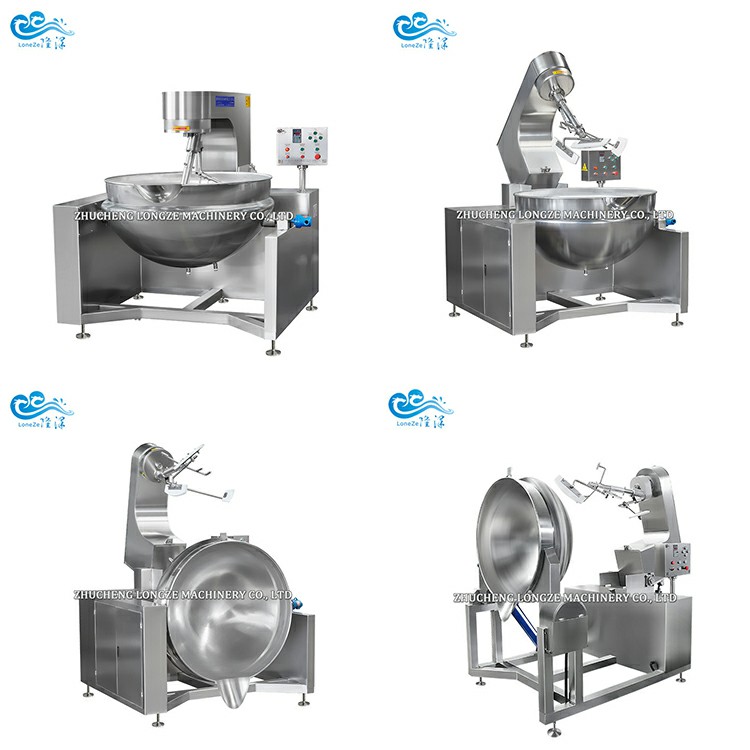

Because this kind of jacketed kettle with mixer is different from the ordinary pan at home, it is composed of two layers of pans, with a sandwich in the middle. A heating medium (heat transfer oil, gas or steam) can be passed into the sandwich to heat the food, because the whole bottom of the pan The temperature is the same, so the product will be heated more evenly. The mixing system is mainly driven by a motor or a hydraulic station. The 360-degree bottom scraping stirring without dead corners is used to avoid the production of the paste pot, and the temperature and mixing frequency can be freely controlled. , So as to ensure that the color and taste of each pot is consistent.

Features: The electric heating jacketed kettle with mixer uses 380V power as the heat source. It is heated by heat-conducting oil. The jacket is equipped with electric heating rods, electric thermocouples and heat-conducting oil (self-matching). The maximum temperature can reach 320 degrees. It is controlled by an electric control box and equipped with automatic temperature. Control System. The electric heating jacketed kettle with mixer has the characteristics of large heating area, uniform heating, high thermal efficiency, short liquid boiling time, and easy control of heating temperature.

Industrial jacketed kettle with mixer configuration:

1. Stirring method: frame-type wall scraping paddle, with directional choke paddle, power 0.75KW, rotation speed 0-60 rpm, Delta frequency converter speed regulation, Siemens, reducer. Stirring paddle material: SUS304 stainless steel; scraper material: polytetrafluoroethylene.

2. Sealing form: mechanical seal.

3. How to open the cover: open the cover through the manhole.

4. Discharging method: discharging or pressing the material by the valve at the bottom.

5. Temperature display: thermal resistance thermometer (less than or equal to 140 degrees).

6. Vacuum degree: pressure vacuum gauge, vacuum gauge≦-0.09Mpa.

7. Heating and cooling method: jacket electric heating, tap water cooling.

8. Capacity design: design volume 130L, working volume 100L.

9. The main process parameters: jacket working pressure 0.03MPa, inner pot working pressure -0.09-0.02MPa.

10. Material used: inner pot material SUS304 stainless steel, thickness 6mm, jacket material SUS304 stainless steel, thickness 6mm, shell material SUS304 stainless steel, thickness 3mm.

11. Upper pot cover: material: SUS304 stainless steel, thickness: 6mm, attached (vacuum pressure gauge, vent valve, vacuum port, mirror light, mirror port with scraper, manhole, spice funnel;).

12. Polishing grade: The inner and exposed parts of the pot are larger than 300 meshes.

13. Vacuum pump: water ring vacuum pump 0.55KW, select Zibo brand.

14. Heating method: electric heating, heating power 6KW*2 equal to 12KW, heating time of the whole pot is about 10 minutes.

15. It is recommended to choose an operating platform above 300L: with step stool, patterned non-slip aluminum plate 16. Jacket liquid level display: magnetic flap level gauge

Maintenance of jacketed kettle with mixer:

1. When unpacking, check whether the product and accessories are consistent with the packing list. During the transportation, whether the product and parts are damaged. If there is any loss or damage, please contact our company in time to solve it.

2. The product has been tested for performance before leaving the factory, and the relative positions of all parts have been installed and adjusted. The user generally only checks it and must not disassemble it at will, so as to avoid improper reinstallation and adjustment, which will affect the performance of the product.

3. The equipment does not need to be fixed, it only needs to be placed on a flat concrete floor.

4. When using a stirred jacketed kettle with mixer, the power supply should meet the requirements of the stirring structure of the equipment, and the equipment casing must be well grounded to avoid leakage accidents.

5. During installation and use, care should be taken to ensure that the oil inlet pipeline is unblocked and free of obstruction.

6. Tighten the two setscrews on the support frame. When shaking the pot, the oil inlet and outlet pipes at both ends are not allowed to rotate with the pot.

7. Valves are not allowed to be installed at the overflow port.

8. When discharging, first open the lid of the pot, and then turn the hand wheel to tilt the pot so that the material is discharged from the discharge port.

9. Vertical electric heating jacketed kettle with mixer. When discharging, the material should be discharged from the outlet of the bottom of the pot.

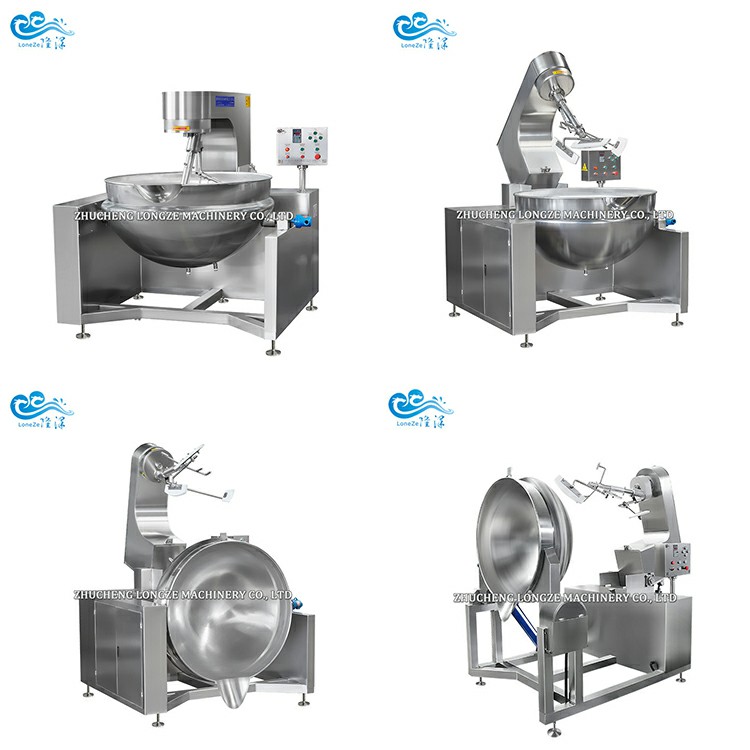

Features: The electric heating jacketed kettle with mixer uses 380V power as the heat source. It is heated by heat-conducting oil. The jacket is equipped with electric heating rods, electric thermocouples and heat-conducting oil (self-matching). The maximum temperature can reach 320 degrees. It is controlled by an electric control box and equipped with automatic temperature. Control System. The electric heating jacketed kettle with mixer has the characteristics of large heating area, uniform heating, high thermal efficiency, short liquid boiling time, and easy control of heating temperature.

Industrial jacketed kettle with mixer configuration:

1. Stirring method: frame-type wall scraping paddle, with directional choke paddle, power 0.75KW, rotation speed 0-60 rpm, Delta frequency converter speed regulation, Siemens, reducer. Stirring paddle material: SUS304 stainless steel; scraper material: polytetrafluoroethylene.

2. Sealing form: mechanical seal.

3. How to open the cover: open the cover through the manhole.

4. Discharging method: discharging or pressing the material by the valve at the bottom.

5. Temperature display: thermal resistance thermometer (less than or equal to 140 degrees).

6. Vacuum degree: pressure vacuum gauge, vacuum gauge≦-0.09Mpa.

7. Heating and cooling method: jacket electric heating, tap water cooling.

8. Capacity design: design volume 130L, working volume 100L.

9. The main process parameters: jacket working pressure 0.03MPa, inner pot working pressure -0.09-0.02MPa.

10. Material used: inner pot material SUS304 stainless steel, thickness 6mm, jacket material SUS304 stainless steel, thickness 6mm, shell material SUS304 stainless steel, thickness 3mm.

11. Upper pot cover: material: SUS304 stainless steel, thickness: 6mm, attached (vacuum pressure gauge, vent valve, vacuum port, mirror light, mirror port with scraper, manhole, spice funnel;).

12. Polishing grade: The inner and exposed parts of the pot are larger than 300 meshes.

13. Vacuum pump: water ring vacuum pump 0.55KW, select Zibo brand.

14. Heating method: electric heating, heating power 6KW*2 equal to 12KW, heating time of the whole pot is about 10 minutes.

15. It is recommended to choose an operating platform above 300L: with step stool, patterned non-slip aluminum plate 16. Jacket liquid level display: magnetic flap level gauge

Maintenance of jacketed kettle with mixer:

1. When unpacking, check whether the product and accessories are consistent with the packing list. During the transportation, whether the product and parts are damaged. If there is any loss or damage, please contact our company in time to solve it.

2. The product has been tested for performance before leaving the factory, and the relative positions of all parts have been installed and adjusted. The user generally only checks it and must not disassemble it at will, so as to avoid improper reinstallation and adjustment, which will affect the performance of the product.

3. The equipment does not need to be fixed, it only needs to be placed on a flat concrete floor.

4. When using a stirred jacketed kettle with mixer, the power supply should meet the requirements of the stirring structure of the equipment, and the equipment casing must be well grounded to avoid leakage accidents.

5. During installation and use, care should be taken to ensure that the oil inlet pipeline is unblocked and free of obstruction.

6. Tighten the two setscrews on the support frame. When shaking the pot, the oil inlet and outlet pipes at both ends are not allowed to rotate with the pot.

7. Valves are not allowed to be installed at the overflow port.

8. When discharging, first open the lid of the pot, and then turn the hand wheel to tilt the pot so that the material is discharged from the discharge port.

9. Vertical electric heating jacketed kettle with mixer. When discharging, the material should be discharged from the outlet of the bottom of the pot.

Contact Us:

Shandong Longze Machinery Co.,Ltd

Company website:https://www.firemixer.com/

WhatsApp/Wechat:0086 13153609533

Tel:0086 13153609533

E-mail:rena@loneze.com

Address:Zhucheng Economic Development Zone, Shandong Province, the first five lines west

Contact:Ms. Rena

If you have any question you can contact me ,i can give you the lowest discount.

Please fill in the form and leave a clear message. We will contact you immediately.