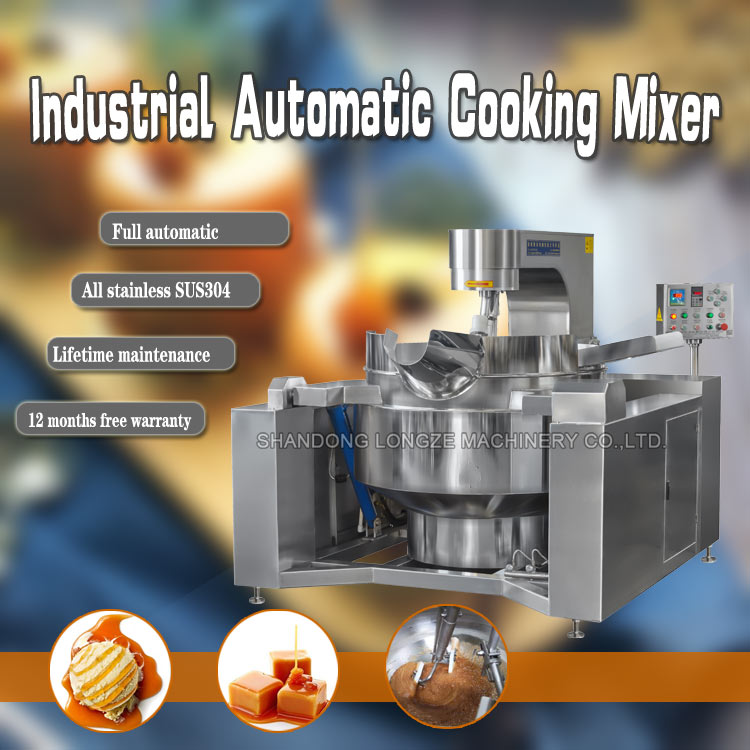

All The Materials Of Our Industrial Automatic Cooking Mixer For Caramel Equipment Are Made Of 304 Stainless Steel, Including Every Screw. Our Equipment Has A Long Service Life And Can Be Cost Reduced. In Addition, Our Industrial Automatic Cooking Mixer For Caramel Equipment Uses Motors Imported From Taiwan And Is Free To Maintain Within Five Years. If You Have Any Questions, Please Contact Me For Free Replacement.

Advantages of Gas Industrial Automatic Cooking Mixer For Caramel:

1) Cooking Bowl Titled To 90° Hydraulically To Allow Easy Discharge Of Food Materials.

2) Stable While In Operation And Movable With Heavy Duty Casters.

3) Wide Application For All Kinds Of Food Or Snack Stuff.

4) Safe Operation With Automatic Pressure Release Valve, Thick Steel Reliable Under Pressure.

5) Fully Automatic With User-Friendly Control Panel.

6) High Capacity Volume Upto 800 Liters.

7) All Stainless Steel 304, Durable And Easy To Clean, Healthy For Food Materials.

8) Planetary Mixing System Enables Fully Mix Inside The Bowl And Without Any Missing.

9) Thick Steel Material Strong Enough To Hold The Body Stable Without Shaking While Mixing With Max. Speed.

10) Heating Temperature Is Easily Monitored And Controlled On The Panel With Wireless Devices Or Direct Detecting.

11) Variable Mixing Speed To Satisfy Various Processing Procedures.

12) Th Scrapers Durable Under High Temperature, Non-Sticky And Anti-Corrosion, Pressed Tight To The Surface Of The Bowl With Strong

Spring. With Side Scraper To Clean Splashes On The Higher Level In The Bowl.

13) Mixing Arm Tilted Backwards Automatically Before Discharging.

Gas Industrial Automatic Cooking Mixer For Caramel Product Description:

13) Mixing Arm Tilted Backwards Automatically Before Discharging.

Gas Industrial Automatic Cooking Mixer For Caramel Product Description:

| Product Description | Gas Industrial Automatic Cooking Mixer For Caramel |

| Bowl size | 100L~500L, 700mm~1200mm dia., 5mm thickness; SUS304 |

| Voltage | 380V/3Ph/50Hz or as customized |

| Power | 3.7Kw~5.5Kw, |

| Capacity | 50kg-350Kg per batch |

| Steel grade | All stainless SUS304 |

| Automation | Full automatic |

| Heating source | Gas Heated |

| Max. temperature | 260℃,higher with copper scrapers |

| Mixing style | Double planetary mixing to avoid burnt |

| Mixing speed | Variable & adjustable |

| Applications | Universal to cook and mix all kinds of spices & sauces, jam, paste, confectionery, nuts, sweets, fillings, vegetables,…… |

All our Automatic Cooking Mixer For Caramel full body is made of stainless steel 304, world recognized suitable and healthy steel for food materials. Exceptfor electric and hydraulic parts, almost all parts are fabricated in our factory with laser machines to ensure their accuracy andcompatibility with each other and thus reduce occurrence of breakdown. It has been repeatedly tested in our factory to achieve itsbest operation and function.

Our Automatic Cooking Mixer are designed with planetary mixing system to thoroughly mix all materials in the pot, without any missing point. It'spositioned steadily while the mixing is even at the maximum speed.

Shandong Longze Machinery Co., Ltd. (“Longze Machinery” in short), officially established in 2012, based in Zhucheng City, Weifang, Shandong Province, China, is a professional manufacturer of cooking and mixing machinery for food and snacks, including industrial popcorn machine, planetary cooking mixer, jacketed kettle, pressure/vacuum cooker, which are universal to make spices, chili sauce, curry sauce, fruit jam, sweets, Halva, paste, nougat, candied fruits, coated nuts, fillings, vegetables, meat------

Advanced Manufacturing Machinery And Techniques:

We are proud of our staff, who are responsible and with rich experience. Combination with our staff first-class skill and the aid of our big scale laser machines, our products are highly commented by our customers and thereby help us earn more regular customers.

Packing And Delivery:

Our machine is packaged in wooden box for overseas shipment, and inside is also protected for easily damaged parts. Wooden box is strong enough and we have not encountered any shipment accident.

We have shipment every day and have our own logistics department for handling packaging and delivery, to ensure on-time delivery safely without any delay.

Customers' Visiting & Testing:

For visiting customers, our company will arrange local transportation and accommodations, and provide necessary materials for testing with our machines. We have various types of machines available for customers' testing in our factory.

Please fill in the form and leave a clear message. We will contact you immediately.